Fully Charged

|

|

Time to read 6 min

|

|

Time to read 6 min

When it comes to selecting the right auxiliary battery for your 4WD or camper, it often comes down to what accessories you’re going to connect to it, how much you are willing to spend, and where you want to install it.

Once you have answered these questions, you need to decide how you are going to charge the auxiliary battery, because the method you use can be impacted by the type of battery chosen as well as the type of alternator your vehicle has.

With the help of Darran Sexton, R&D Manager for Ironman 4x4, we’ve come up with some options to help you with your setup.

BATTERY TYPES

There are several different types of batteries used as auxiliary batteries in a 4WD or house battery in a camper, each with their positives and negatives, so let’s see what they are.

Calcium: While similar in cost and weight to the lead-acid battery, calcium batteries do hold some advantages, such as reduced gas venting, less water usage, higher resistance to corrosion and a lower self-discharge. Being sealed, calcium batteries are maintenance-free but, as they still do vent dangerous gases, they cannot be installed inside the cabin of your 4WD. Calcium batteries are reputed to offer an improved tolerance to heat and corrugations but, having replaced four calcium batteries over two years, I will never buy one again.

Lithium: The new kid on the block and a real game-changer, albeit expensive. LiFeP04 lithium batteries are three times lighter, charge much faster and discharge longer and slower than the batteries already discussed. They also have more usable power with almost 100 per cent available, compared to only 50 per cent with lead-acid and AGM batteries and discharging to these low levels doesn’t affect its lifespan. These batteries are sealed, so can be installed anywhere, except (at this stage) the hot engine bay. They can also be mounted on their side or their end, meaning they can be hidden away in tight spaces. Having installed lithium batteries in my Prado and my camper, I believe once you try lithium, you’ll never go back.

MODERN ALTERNATORS

The introduction of smart alternators on modern 4WDs meant aftermarket charging methodology had to change as compared to fixed voltage alternators. A fixed voltage alternator produces a very high voltage, more than enough to charge both the cranking battery and the second battery.

The smart alternator reduces the amount of charge it produces according to the operational conditions of your 4WD, meaning your auxiliary battery will not be recharged correctly.

As Sexton explains: “The smart alternator has a varied output to deal with stringent emission regulations, reduced fuel consumption targets and the vehicle’s operational loads. Due to the smart alternator’s variable output and the vehicle’s OEM battery management system, the auxiliary battery may not charge correctly when the cranking battery is fully charged. The vehicle’s inbuilt battery management system reduces the alternator's output, leaving nothing for the auxiliary battery.”

BATTERY MANAGEMENT SOLUTIONS

It is important to select the right battery management solution (BMS) to suit your setup. There’s no point trying to save some money and buying a simple isolator that uses a solenoid if you’re looking at installing a lithium battery,

for instance.

By the same token, don’t bust the bank buying an intelligent BMS system if all you want is something to charge the lead-acid battery that only runs the fridge twice a year on camping trips. As Goldilocks once said: “The one in the middle is just perfect.” In this case, it’s a DCDC charger, because this charger has the features to provide a reliable and stable charge to any type of auxiliary battery.

DIY INSTALLATIONS

Installing an auxiliary battery into your 4WD or camper is something that some people are keen to do themselves, and I’ve always been one of them. The one thing I have learnt is that reading the instructions is very important, but also that sometimes the instructions miss a vital piece of information, which can lead to dire circumstances.

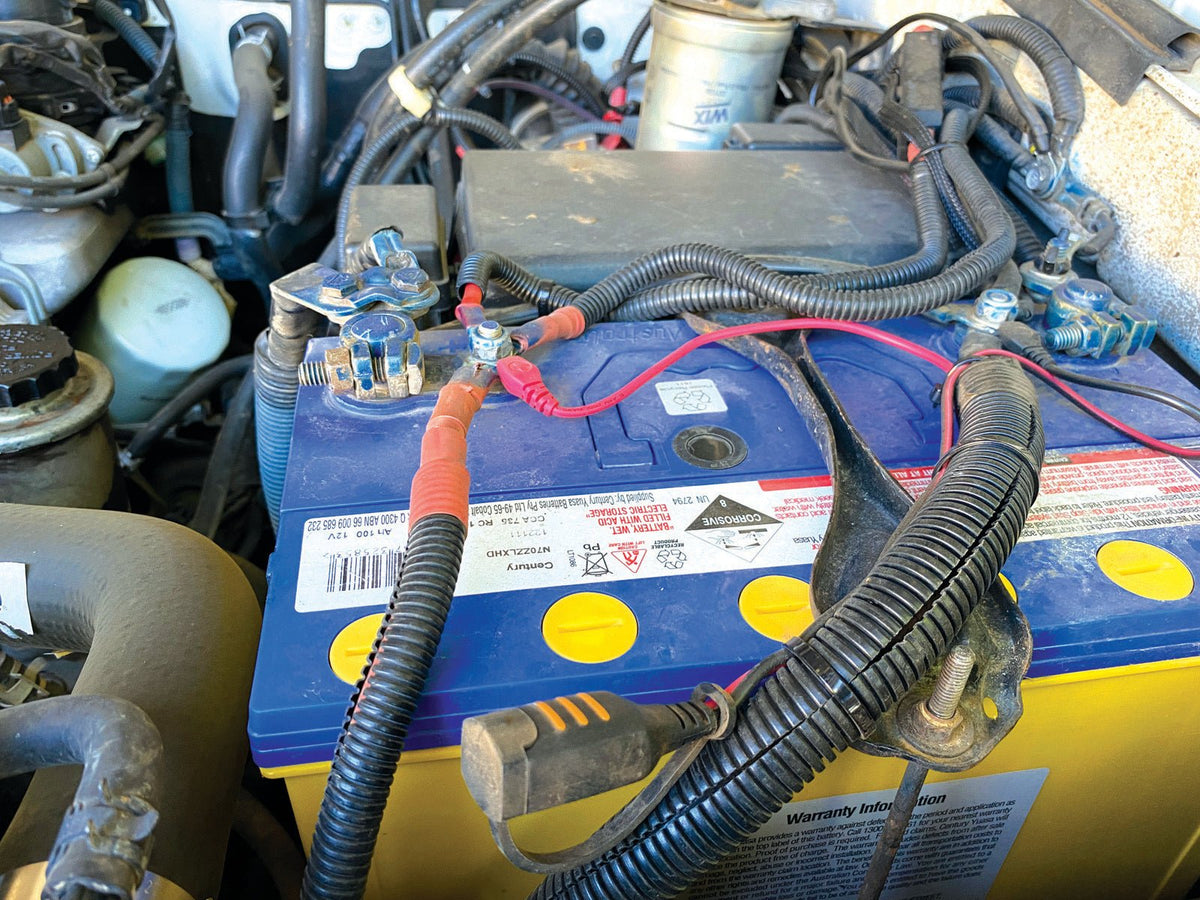

I’d replaced a faulty isolator between the cranking battery and the auxiliary battery with another brand, using the existing wiring as I was about to leave on another trip. Further down the track, while using a 240V charger on my cranking battery that had dropped a cell, the battery sent crazy amps to the isolator and it caught fire.

Thankfully, I discovered the fire in time and was able to extinguish it with minimal damage in the engine bay. Had the instructions for the original isolator mentioned the need for a fuse between the cranking battery and the isolator, this would never have happened.

Sexton has the following tips for a DIY install: